Applications & technical details

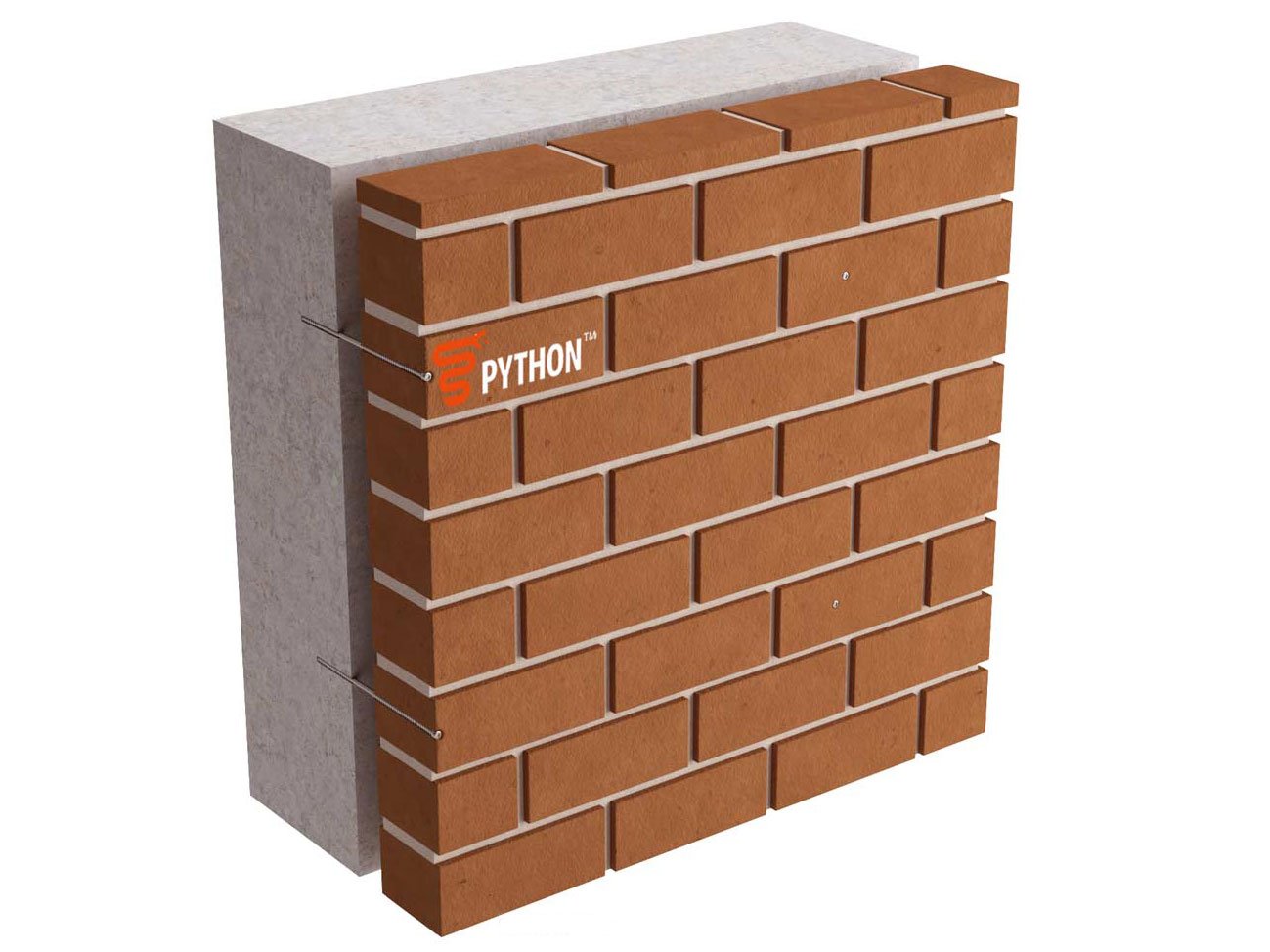

A state-of-the-art cavity tie system, developed to provide a robust and reliable structural interconnection of double brick walls.

When used at code maximum spacings, the PYTHON C cavity tie induces partial composite out-of-plane behavior which builds in structural resilience not obtained with historical methods such as the use of flexible cavity tie systems. This is a great way to build in additional structural resilience when replacing corroded, poorly installed, non-existant or otherwise insufficient existing cavity ties.

When used at recommended spacings for strengthening, the PYTHON C cavity tie induces full composite out-of-plane behavior in double brick walls. This technique enables double brick walls to behave as equivalent solid walls, increasing the out-of-plane performance by up to five times that of a double brick wall with flexible cavity ties. The PYTHON C cavity tie has been widely adopted as a cost effective method to strengthen existing double brick walls and is supported by some of the world’s most extensive full scale semi-static cyclic and dynamic testing using best practice research methods.

PYTHON’s cavity-wall ties are minimally invasive and fully reversible, offering quick and simple installation, subject to design, fully concealed or a subtle appearance.

APPLICATIONS

Structural interconnection of masonry cavity walls and veneers.

Earthquake strengthening of URM cavity walls and veneers.

Remediation of existing cavity and veneer ties.

FEATURES

Enables cavity walls and veneers to behave as a composite action, drastically increasing their out-of-plane performance.

Simple design procedure with recommended spacings.

The only remedial cavity tie with a verified shear capacity.

No unwinding under cycling loading, strong hold to a variety of masonry substrates.

Dry and clean installation, no epoxy required.

Technical

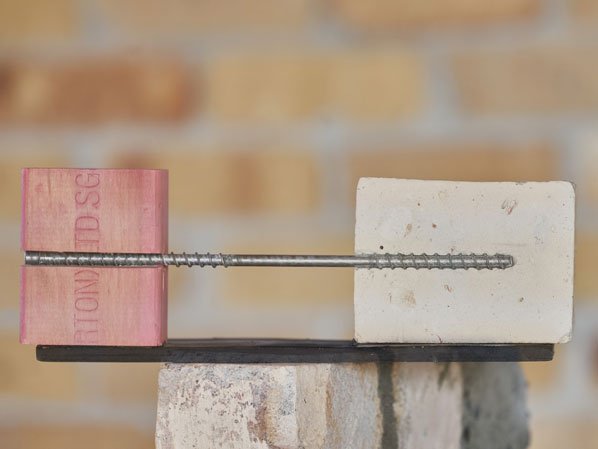

Nominal shank diameter of Ø6mm with total 240 mm standard length.

Zinc-Nickel coating, R4 (external, coastal environments) durability classification in accordance with AS/NZS 2699.1 & AS 3700. Tested in accordance with ASTM B117:2019 to 1500 hours of salt spray exposure (Read more).

Technical engineering design data tested for a range of masonry substrates available (Read more).

Example construction details available (Request).

On-site quality assurance proof testing on request (Contact us).